| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : MENTO

Model Number : K2005DT

Certification : FCC.ROHS,CCC

Place of Origin : DONGGUAN

MOQ : 3

Payment Terms : L/C, T/T

Supply Ability : 10pcs+20 work days

Delivery Time : 20 work days

Packaging Details : 1200mm*1500mm*1800mm

Product Type : Automatic Optical Inspection Equipment

Inspection Method : Automatic

Resolution : Up to 5μm

Operating System : Windows

Defect Classification : Automated classification and sorting

Optical System : High-resolution camera

Data Management : Real-time data analysis and storage

Software : Advanced image processing software

Field Of View : Up to 300mm x 300mm

| 2D Automated Optical Inspection Online dual track | ||

| Model | K2005DT | |

| Testing Capability | Test items | CHIP component body, CHIP component solder joints, characters, DIP solder joints |

| Minimum component | CHIP:01005 Pitch:0.3mm | |

| Detection Method | Algorithm Parameter Debugging, Machine Learning | |

| Optical System | Camera | 5MP high speed color industrial camera |

| Telecentric Lens | 0.345X/0.22X/0.17X | |

| Resolution | 10um/15um/20um | |

| FOV | 24x20mm/36x30mm/48x40mm | |

| Detection Speed | 3FOV/s | |

| Software System | Operating System | Windows10 |

| Mechanical Properties | PCB thickness | 0.3~10mm(Warp≤5mm) |

| Component Height | Upper 30mm, lower 84mm(special height can be customized) | |

| Driving device | Servomotor+Ball Screw+Linear Guideway | |

| Moving speed | Max.600mm/s | |

| Positioning accuracy | ≤8um(after calibration) | |

| PCB transport guide | PCB rail transportation height:900+20mm(from ground to PCB rail transportation surface) | |

| PCB maximum size: 600mmxW300mm (dual rail, double PCB) 600mmxW580mm (single rail, single PCB) | ||

| Minimum distance between PCBs:≤90mm | ||

| Parameters | Curing method | AC220V/50Hz/2000W |

| Detection screen | W1000mmxD1380mmxH1600mm(without foot 100±20mm) | |

| Accuracy | 1100KG | |

| Re-measurement Accuracy | ≥0.5MPa | |

| Wafer Ring Size | Temperature:5~40℃, relative humidity 25%~80%(no frost) | |

| Number of wafers handledsimultaneously | Standard SMEMA interface | |

Product testing capabilities(Online Dual-Track)

1.Misplacement 2. Missing Component 3. Polarity Reversal 4. Non-Wetting 5. Solder Hole 6. Collinear Anomaly 7. Poor soldering 8. Pin Warpage

9. Insufficient Soldering 10. Short Circuit 11. Offset 12.DIP Component Missing 13.DIP pins unextended......

MES data docking function and powerful SPC system

1. Real-time statistics of the top10 alarm components

2. Enables setting an alarm count to automatically halt upstream equipment.

3. Export the entire board image of each PCB in real time for subsequent traceability

4. Indigenously developed MES interface supports standard and customized formats.

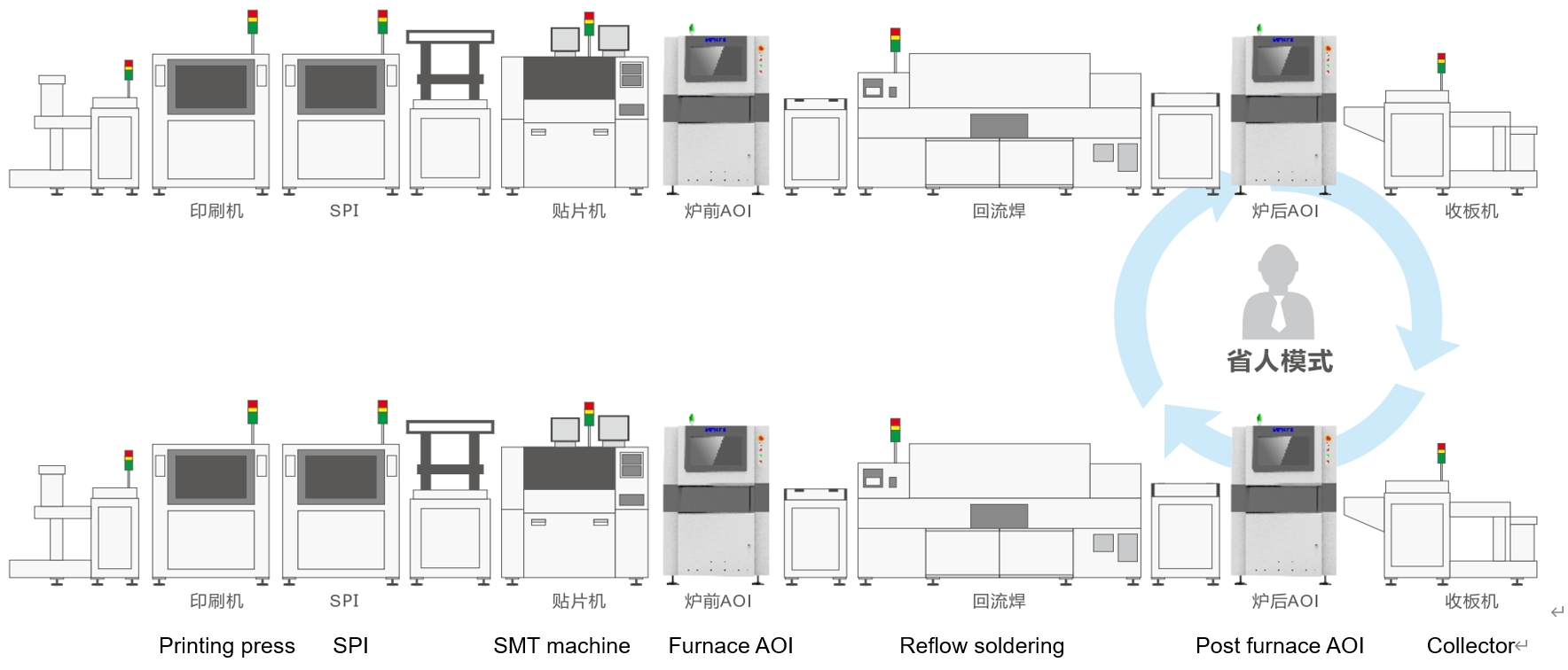

Labor-saving mode

Through data transmission and other methods, one person can view the AOI alarm data of multiple lines, thereby realizing a man-saving mode.

|

|

ROHS Automated Optical Inspection PCB SPI Machine Real Time Data Analysis Images |